STAMPING & LASER TRIM

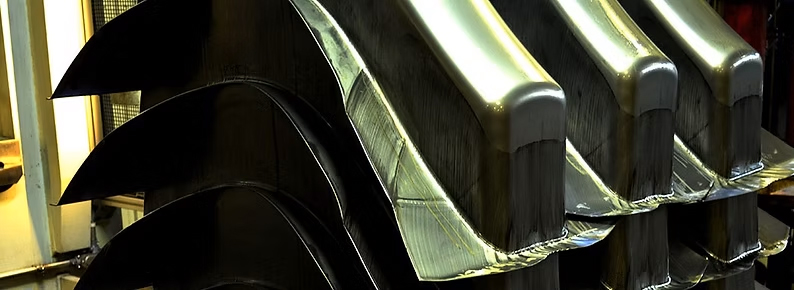

Stamping

Utilizing stamping presses that range up to 500 tons, Envision Engineering has the flexibility to handle your stamping needs. We specialize in deep draw forming Class “A” parts as well as progressive and transfer tooling. We have years of experience dealing with specialty projects as well.

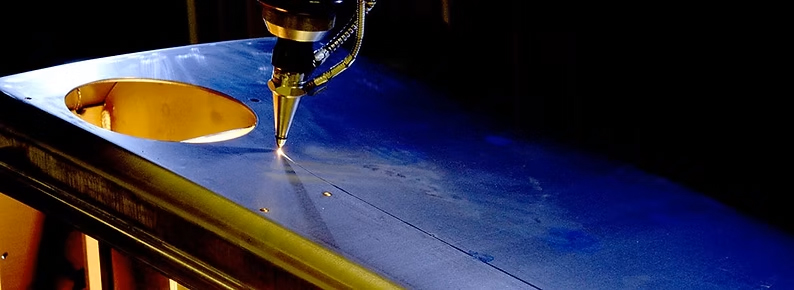

Laser Trim

By offering in-house laser cutting, we are able to offer a higher level of flexibilty and quality to our customers. With both flat and 5-axis capabilities, and lasers exceeding 4000 watts that can cut steel up to .500″ thick, we are well equipped to handle any laser trim job.

A bonus of having five axis laser capabilities, is the ability to offer multiple configurations of the same product. This drastically helps our customers save money.

Surface Treatment

If your product has special surface treatment requirements, we have a strong vendor base; capable of adding almost any type of finish. Please visit our “Surface Finish” page for more information.

Some of the finishes we have experience working with:

E-Coat

Powder Coat

Galvanized (Pre-Forming)

Aluminized (Pre-Forming)

Heat Treat

Liquid Paint (Applied directly to e-coated surface or primer)